JTEC Corporation’s Plasma CVM Technology

Plasma Chemical Vaporization Machining

(Plasma CVM)

JTEC Corporation provides innovative solutions in semiconductor and quartz wafer planarization processing using Plasma Chemical Vaporization Machining (Plasma CVM) technology. Plasma CVM is a technology with excellent features of nano-level processing accuracy and no process alteration layer (no damage to the surface of the workpiece).

Advantages of our Plasma CVM

POINT

Numerical Control Technology

Nano-level processing accuracy

High-precision planarization process

Reduction of thickness variation

POINT

Atomic-scale processing

No process alteration layer is generated(Damage-less)

Contribution to quality improvement and electrical characteristics

POINT

Chemical reaction

Suitable for various wafers

Crystal (SiO2), silicon (Si),

SOI, GaN, etc.

Advantages of Plasma CVM

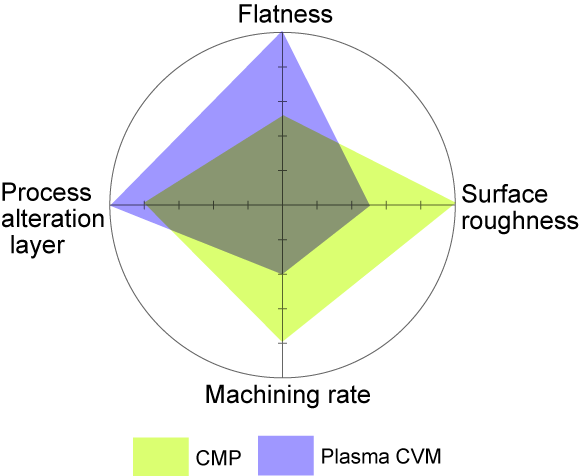

Plasma CVM is a unique technology that uses only chemical reactions as its processing principle, which is distinct from CMP and ion beam processing, which remove by mechanical action. Plasma CVM achieves high-precision planarization that cannot be achieved by CMP and does not cause damage as ion beam processing does. Plasma CVM can contribute to process simplification and cost reduction, as post-processing cleaning may not be necessary depending on the subsequent process.

Improvement of wafer performance

Further planarization of wafers after CMP

Improved wafer quality

Provides a high quality surface without the worry of process alteration layer

Reduces wafer manufacturing costs

Contributes to cost reduction by simplifying the process

Complementary relationship with CMP

Plasma CVM significantly improves the planarity of wafers polished by CMP.

By combining CVM and CMP in a complementary process, wafers of higher quality than ever before can be obtained.

Polishing by CMP

Polishes wafer surfaces to improve roughness, high polishing rate

Plasma CVM for better planarity

Improvement of wafer flatness by numerically controlled processing, removal of process alteration layer generated by CMP

Environmental Considerations

Plasma CVM is a wafer processing by gas phase chemical reaction, and although exhaust gas treatment is necessary, it does not use chemicals that incur wastewater treatment costs.

It is a solution that realizes high-quality, high-performance wafers in a dry environment.

Please click the button below to contact us with any questions or for more information.

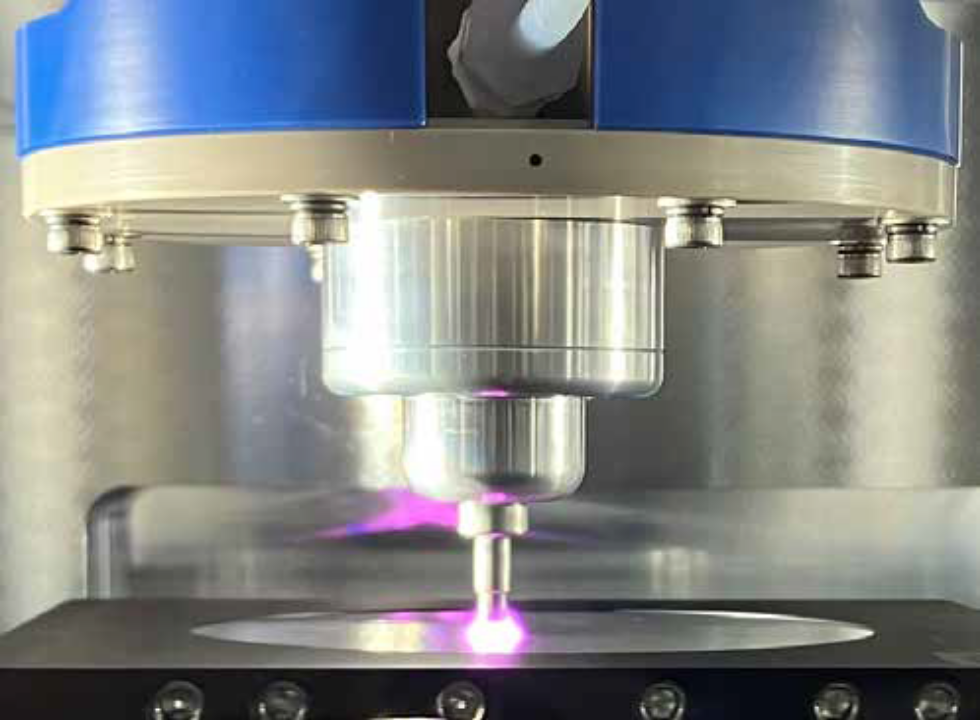

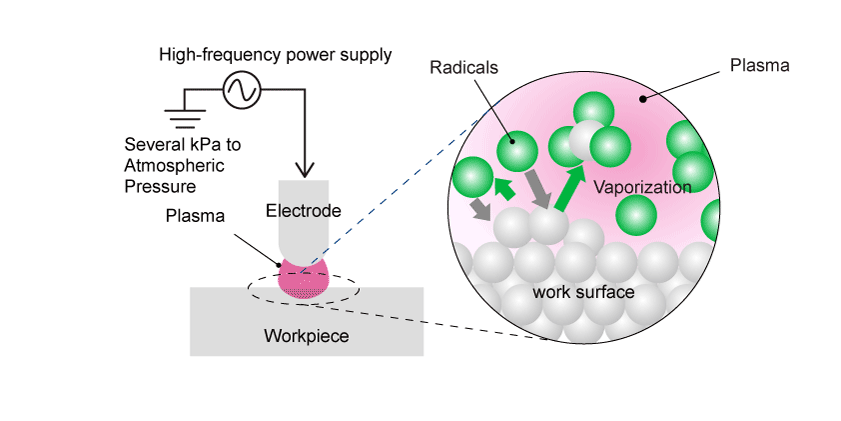

Principle of Plasma CVM that realizes atomic-scale processing

Excellent processing efficiency

Chemical reactions using high-density neutral radicals from high-pressure plasma enable processing with higher processing efficiency than conventional plasma etching, contributing to higher productivity.

Atomic-scale high-precision processing

Plasma CVM can generate plasma locally, enabling machining with high spatial resolution. This makes it an excellent match for numerically controlled machining, and it achieves excellent planarization of wafers through atomic-scale high-precision machining.。

Realizes damage-free wafer processing surface

Plasma CVM, which is characterized by processing by chemical reactions, does not produce a process alteration layer on the processed surface of the wafer. This contributes to higher quality and performance of electronic components using wafers processed by Plasma CVM.

Examples of Plasma CVM Processing

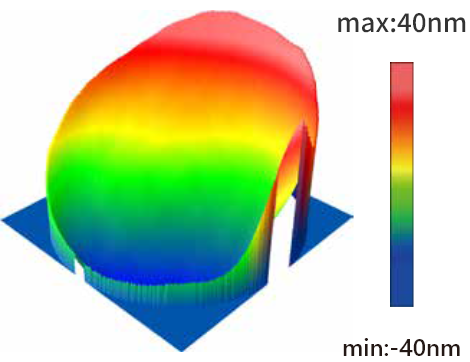

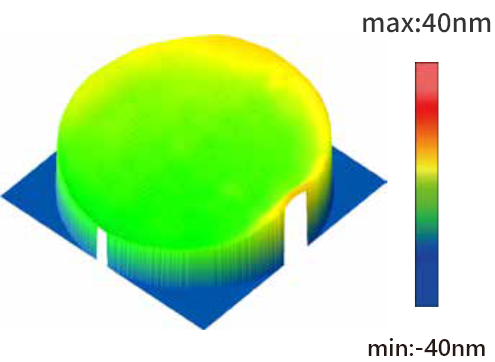

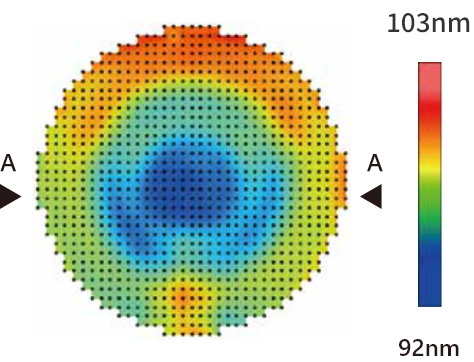

Quartz crystal

Pre-processed quartz wafer: 4-inch (100 mm)/commercially available

Measurement range: Area within a circle of 100 mm diameter

BEFORE

Pre-processing thickness distribution

TTV: 102 nm

AFTER

Thickness distribution after processing

TTV: 18 nm

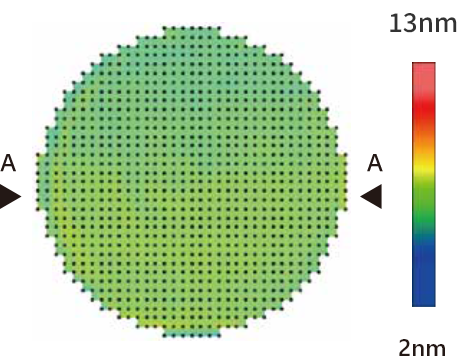

SOI

Pre-processed SOI wafer: 8-inch (200 mm)/commercially available

Thin film SOI wafer (SOI layer: 100 nm, embedded oxide layer: 200 nm)

Measurement points: Area within a 190 mm diameter circle, 5.5 mm grid

BEFORE

Thickness of SOI layer before processing

Average thickness: 97.5 nm

TTV: 9.4 nm

AFTER

Thickness of SOI layer after processing

Average thickness: 7.5 nm

TTV: 3 nm

Improvement of TTV of quartz and SOI by nano-level control

TTV: Total Thickness Variation

The difference between the maximum and minimum thicknesses in the flatness application area of a wafer

Introduction of Plasma CVM Systems

Proposal for further improvement of quality and performance of various types of wafers

(Standard type for development and small-lot production)

(Fully automated type for mass production)

Improved productivity

All processes, from wafer removal from the cassette, thickness measurement, processing, and data storage, are automated. Efficient production is possible without manpower.

Cost Reduction

Compact design minimizes He gas usage and significantly reduces running costs. This system is also environmentally friendly.

Reliable Traceability

All thickness data before and after processing is stored in the system. Quality control is assured.

Features of Plasma CVM Products

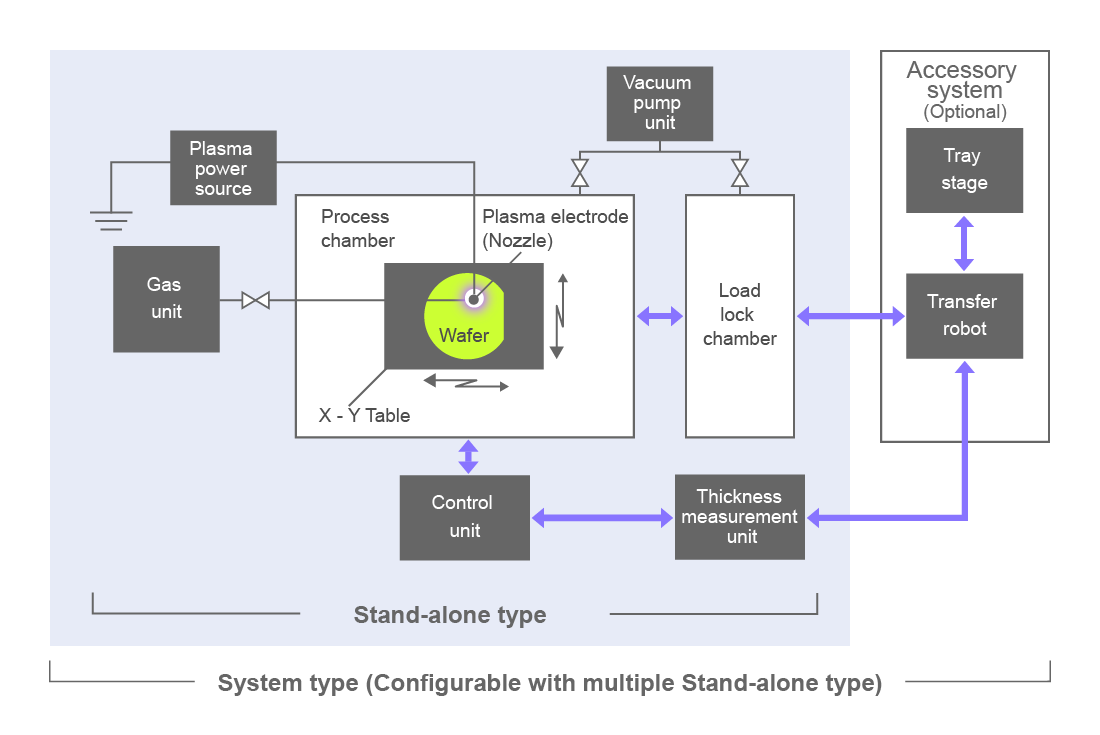

■JC100

Stand-alone type

(Standard type for development and small-lot production)

・Stand-alone type

・Suitable for customers who wish to independently study Plasma CVM

・Load-lock chamber reduces the time required to change samples and enables efficient continuous processing.

・Thickness measuring device is included.

■JC2000

System type

(Fully automatic type for mass production)

・Equipped with a processing unit and a measuring unit, this automatic system calculates the amount of processing based on the measurement data and performs processing.

・System configuration for mass-production processing

・Wafer transfer in the system is performed by transfer robot.

・High throughput is achieved by using multiple processing chambers (two chambers for JC2000).

Steps up to System Installation

STEP

Inquiry

Accepts questions regarding Plasma CVM technology, system, etc.

STEP

Technology introduction

Visit or web conference, depending on your request

STEP

Sample prototyping and evaluation

Test processing is available at any time

STEP

Proposal for rough estimate, detailed system specifications, etc.

We propose the optimal system to meet your needs.

Plasma CVM system consists of a process chamber for processing, a load lock chaber, and a thickness measurement unit.

We can propose optimal system configurations for customers seeking to improve processing capacity and shorten takt time.

If you are interested in producing high-quality, high-performance wafers efficiently and at low cost, please click the Inquiry button below to tell us about your needs.

Plasma CVM System Configuration Example

Plasma CVM system general specifications

| Plasma Chemical Vaporization Machining (Plasma CVM) |

JC100 (Plasma CVM processing system) | JC2000 (Plasma CVM automated machining system) | |

|---|---|---|---|

| Basic configuration | Process chamber | 1 chamber configuration with plasma electrode | 2 chamber configuration with plasma electrode |

| Load lock chamber | 1 chamber configuration | 2-chamber configuration | |

| Degree of vacuum | Achievable vacuum 10 Pa | ||

| Gas type | He / SF6 for process, N2 for purge | ||

| Plasma power source | 13.56 MHz / Max. 300 W | ||

| Control unit | PLC control (partly PC control) | ||

| Thickness measurement unit | Spectral interferometry (for wafer thicknesses from 20 to 100 µm) | ||

| Peripheral system (Option) |

Tray stage | - | Multi-stage loading of trays up to 4-inch size |

| Transport Robot | - | 4-axis (X-axis, Y-axis, Z-axis, θ-axis) robot | |

| Dimensions | W2000 mm × D750 mm × H1600 mm | W2000 mm × D3700 mm × H2200 mm (2-chamber configuration) | |

| Weight | Approx. 1000 kg | Approx. 2500 kg (2-chamber configuration) | |

| Utility | Power source | 3-phase AC200V, 30 A x 1 system | 3-phase AC200V 30 A x 2 systems, single-phase AC100V 15 A |

| Instrumentation Air | 0.4~0.6 MPa | ||

*Please contact us for wafer size.

Company Profile

| Company Name [Trade Name] | JTEC Corporation |

|---|---|

| President and Representative Director | Takashi Tsumura |

| Description of Business | Design, manufacture and sales of X-ray mirrors for synchrotron radiation facilities Development, design, manufacture and sales of automated cell culture system Development, design, manufacture, and sales of various automated systems Development, manufacturing, and sales of surface processing of various materials Support services related to regenerative medicine |

| Capital stock | 837,948,000 yen (as of June 30, 2024: consolidated) |

| Established | 1993/12/21 |

| Location of head office | 2-5-38, Saito Yamabuki, Ibaraki, Osaka 567-0086, Japan |