- Life Science

Opening the Future of Medicine

with Cell Culture Technology

Leveraging over 30 years of expertise in Automated Cell Culture Technology and our proprietary CELLFLOAT platform, we contribute to advancements in regenerative medicine and drug discovery.

Discover Our Technology

Discover Our TechnologyLife Science Products

Discover Our ProductsAutomated Cell Culture System

MakCell

Equipped with a built-in HEPA filter, the CO₂ incubator enables Automated medium change and supports the use of up to three different media types. It accommodates both culture dishes (100 mm / 60 mm) and multiwell plates (6-, 12-, and 24-well), making it suitable not only for maintenance culture but also for differentiation protocols.

CellMeister

By integrating our proprietary automation technologies for cell processing, we can customize solutions to meet each customer’s unique specifications. Automating the handling of large volumes of samplesj, tasks that are challenging to perform manually, enhances both operational efficiency and accuracy.

3D Rotational Floating Culture Equipment

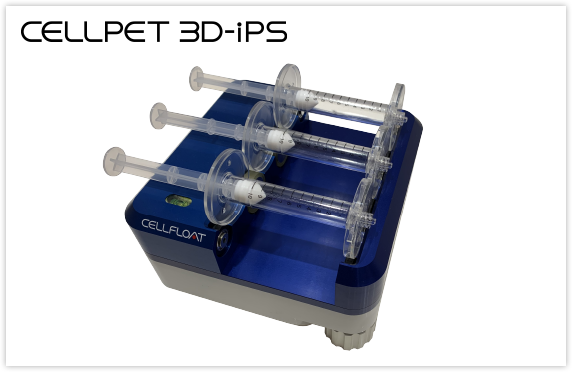

CellPet 3D-iPS

CELLFLOAT utilizes a cylindrical vessel design and is employed from iPS cell spheroid formation through to differentiation induction.

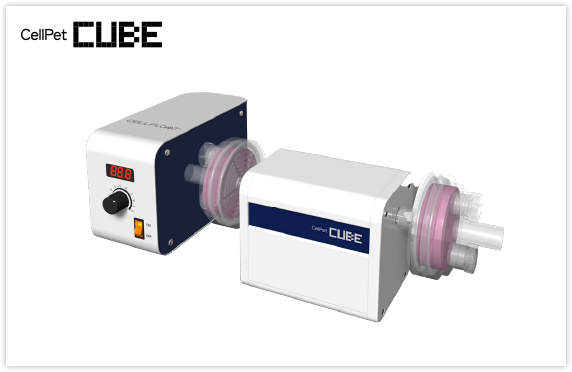

CellPet CUBE

CELLFLOAT utilizes a hollow, disk-shaped vessel featuring two large ports for sample retrieval, enabling tissue culture up to millimeter-scale dimensions.

CellPet 3D-L

Customized CELLFLOAT systems designed to meet your specific requirements. Based on factors such as cell or tissue quantity and size, medium volume, and the need for gas dissolution in the culture medium, we develop, manufacture, and supply dedicated devices and vessels.

CellPet 3D

CELLFLOAT employs a hollow, disk-shaped vessel and serves as a scale-out system for the CellPet CUBE platform. It is utilized for large-scale cultures in non-clinical manufacturing processes etc.

Cell Spheroid Small Fragmentation Equipment

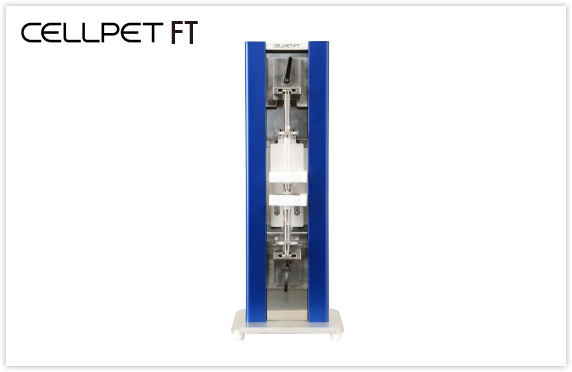

CellPet FT

Without enzymatic treatment, cell spheroids are automatically fragmented or dispersed into nearly uniform sizes through physical processing within a closed-system environment.

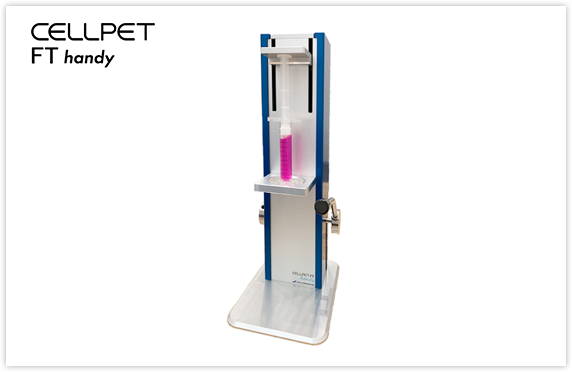

CellPet FT handy

A device that enables manual operation of the CellPet FT cell fragmentation system, featuring a compact design suitable for use within a safety cabinet.