Optical

Product introduction

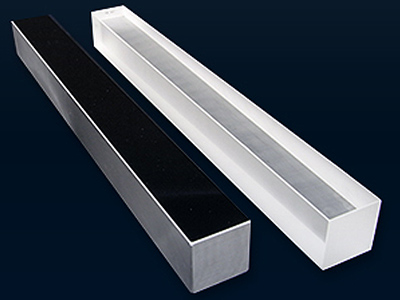

JTEC Corporation's high-precision X-ray mirrors are manufactured using EEM fabrication technology to achieve nanometer order difference from the design shape. Our optical surfaces have RMS 0.1 nm or less of micro roughness, implying almost no unevenness. This results in excellent X-ray focusing performance that exceeds what is possible with other focusing mirrors.

Due to the total reflection mirror system, our mirrors have no chromatic aberration in comparison with optical elements, such as Zone Plate. Because of our free working distance setting, any optical system can be designed according to what is expected from the experimental equipment.

- Our advantage

-

- High-precision mirror shape

- Free surface shape

- Long mirror capability

(up to 1 meter)

PV is an index for indicating the accuracy of the mirror shape (Peak to Valley: difference in height between the highest and lowest points). We can provide a mirror with a maximum length of 1 m with an accuracy of PV 2 nm or less. We can provide not only flat mirrors, but also a variety of free surface shapes, such as elliptical, cylindrical, spherical, parabolic, and ellipsoidal.

Our advantage is that our mirrors can reflect powerful X-rays uniformly while maintaining the characteristic wavefront produced in large synchrotron radiation facilities.

Specifications of X-ray mirror

| Length | ≤ 1000mm |

|---|---|

| Surface shape |

1-dimension mirror : plane, cylinder, sphere, ellipse, parabola, hyperbola etc. Rotating shape (2-dimension shape) : Ellipsoidal, spheroidal, paraboloidal etc. |

| Material | Silicon, quartz glass, low expansion glass etc. |

| Slope error | <0.05uradRMS |

| Shape error | <1.0nm (PV) (or <0.3nm RMS) |

| Surface roughness | <0.1nmRMS (evaluation area 100μm × 100μm) |

| Coating | Pt, Au, Rh, Pd, Ag, Ni, C, B4C, Cr, etc. |