- Device Development

CARE

CAtalyst Referred Etching

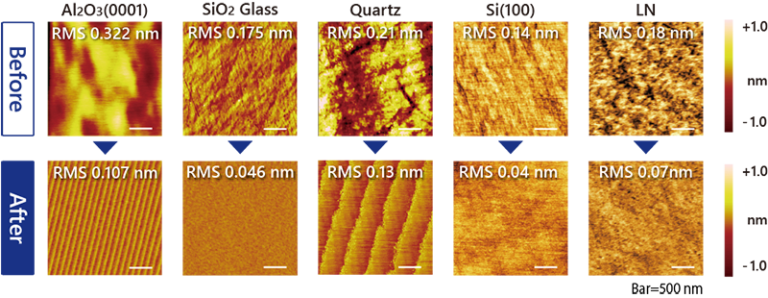

CARE (CAtalyst Referred Etching) is an atomically advanced process using only pure water with metal catalyst action to achieve a surface roughness (RMS) of 0.1 nm or less.

It is used as a final finishing process after surface processing such as CMP* and is applied to improve the performance of LT/LN wafers for SAW devices by mirror finishing and to improve the reliability of bonding by mirror finishing the base substrate of bonded devices.

*CMP: CMP polishing method (Chemical Mechanical Polishing)A polishing method that mechanically polishes the surface of a wafer using a pad and chemicals containing abrasive.

- Workpiece

- SiO2, Si, lithium niobate (LN), lithium tantalate (LT), etc.

- Application Examples

-

- Surface finish of LN substrate for SAW devices (Sa<0.1 nm)

- Surface finish of wafer and bonding (Si, SiO2, etc.) surfaces

- Improvement of junction reliability through cleanliness

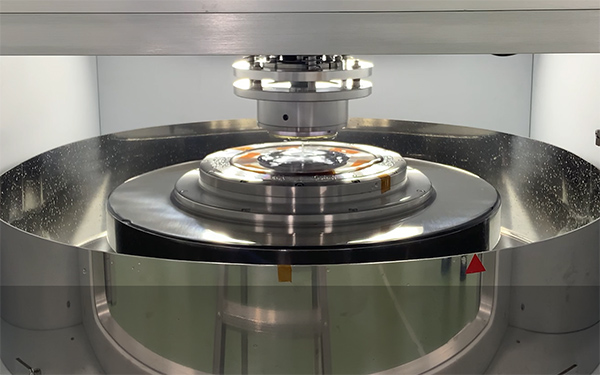

CA1000

Processing stage unit of the CA1000

Video

Processing Flow

■Features

・Achieving planarization through atomic-scale chemical etching using metal catalyst reactions

・Low environmental load processing using only pure water, without any chemical solutions or slurry

・As a final finish after polishing processes such as CMP, creating “atomic-order surfaces” and “surfaces with no altered or modified layers” in a “clean” manner

■Typical Application Examples

・Surface finishing of LN substrates for SAW devices (Sa<0.1 nm)

・Surface finishing of wafers before bonding for bonding devices

Examples of CARE-processed surfaces

Atomically smooth and damage-free surfaces

High potential and applicability to semiconductor material polishing