MakCell

Product Features

MakCell will change culture medium for you!

Automatic medium change in CO₂ incubator

Reduces stress on cells caused by environmental changes such as CO₂ concentration, temperature, and humidity

Reduces damage to cells caused by moving culture vessels (tremor) when changing culture medium (also applicable for dimple plates).

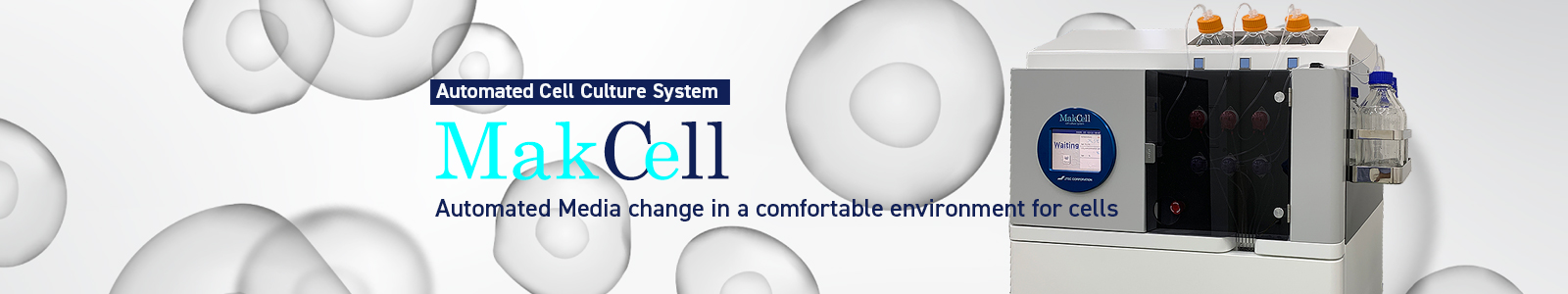

Designed to minimize contamination

“ISO14644-1 Class 5” equivalent cleanliness environment due to circulation in the chamber with HEPA filter

Cleanlines is kept by washing the waste liquid nozzles that come in contact with the medium after medium change.

*The same culture medium supply nozzles and waste nozzles are used until the next tube replacement.

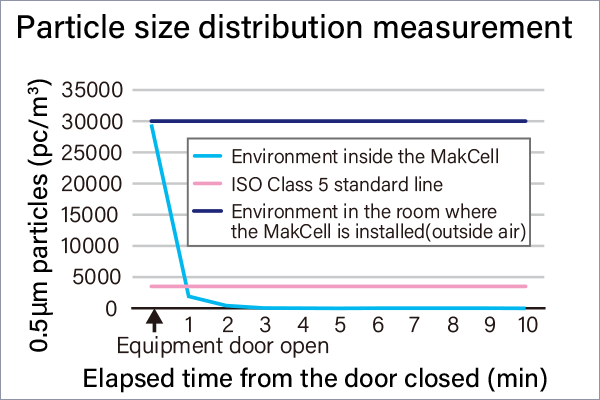

Compatible with both dish and multi-well plates

Capable of operating simultaneously in different types of culture vessels

Settable culture vessels “Φ60 mm / Φ100 mm dish” or “6-well / 12-well / 24-well plate”

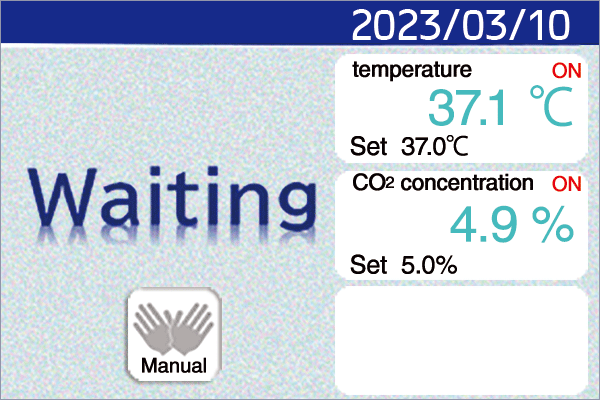

LCD touch panel on the front of the MakCell

LCD display of temperature and CO₂ concentration in the incubator

Manual operation of the MakCell is carried out using this panel.

*Culture condition and schedule can be set up on the control PC.

Three types of culture medium can be set separately (with culture medium cooling function)

Three types of culture medium can be set separately, enabling the supply of culture medium tailored to the cells.

A cooling unit is mounted on the top of the device to prevent the medium from deteriorating.

<About the warning lamp for insufficient medium>

・Lamp illuminates when the cooling section is switched on.

・Lamp flashes when the remaining volume of a 500 mL bottle is less than 100 mL or when the remaining volume of a 1000 mL bottle is less than 200 mL.

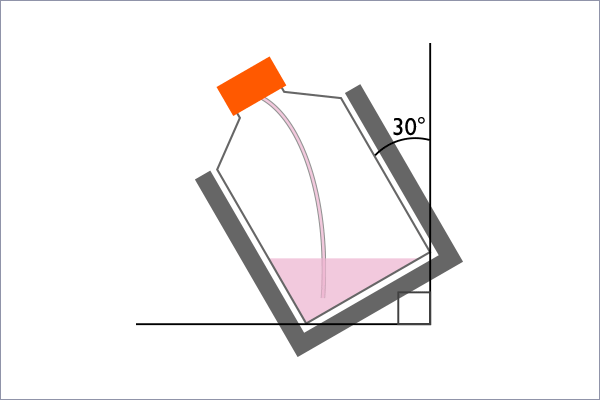

<About the storage angle of the medium bottle>

The bottles are set at a 30-degree angle. This makes it easy to remove the bottle and to suck up the medium without leaving it to the end.

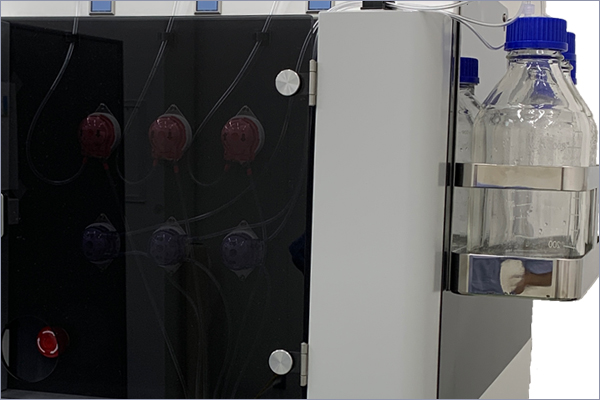

Bottles for collecting discarded medium

Holds up to three wide-mouth medium bottles (1 liter)

Storage in an easy-to-see location makes it easy to check discarded culture medium and prevents forgetting to replace bottles.

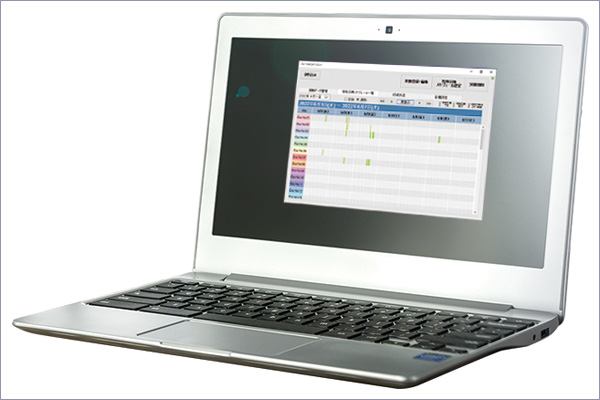

Easy operation with control PC

Culture schedules can be managed on the control PC and up to 50 culture schedules can be registered.

Daily and weekly schedules can be checked at a glance.

Option

eMail notification function

Notification by eMail of the beginning and the end of medium change operations or the occurrence of errors

・The operating status can be checked even outside working hours, such as on holidays, for peace of mind.

・The notification items can be selected according to the settings.

Clean booth

・Installing the MakCell in a clean environment sufficiently lowers the risk of contamination.

・Improved workability

Possible to change medium in a low-oxygen atmosphere

・Cell culture can be carried out while maintaining a low-oxygen concentration environment.

・Controlling the oxygen concentration contributes to optimal cell culture.

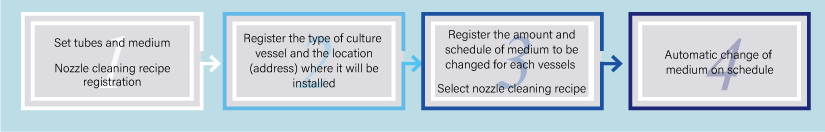

Operation Procedure

Please check the video to see how MakCell works

Application Notes

NEW

Hypoxic culture of HeLa cells using MakCell

We evaluated the cellular response under hypoxic conditions using MakCell. When HeLa cells were cultured in a MakCell incubator set to 1% O₂, HIF1α—a well-known hypoxia response factor—was confirmed to translocate into the nucleus within one hour. Similarly, nuclear translocation of HIF1α was also confirmed in adipose-derived mesenchymal stromal cells.

NEW

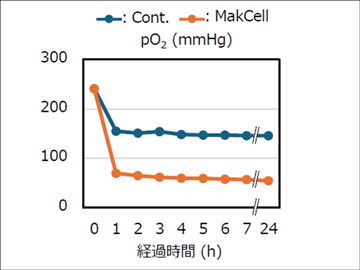

Stability in hypoxic environments of MakCell

We evaluated the stability of MakCell in hypoxic environments. It took approximately 1 hour to go from normal oxygen concentration to hypoxic conditions with 5% O2. We then measured the fluctuations in hypoxia that occurred when the incubator door was opened and closed. After the door was opened for about 5 seconds, the hypoxia returned to the set oxygen concentration in about 6 minutes at the 5% O2 setting and about 12 minutes at the 1% O2 setting. Finally, it was confirmed that the hypoxic condition was maintained without disturbance during MakCell operation.

Cardiomyocyte differentiation from human iPS cells using MakCell

Differentiation of human iPS cells into cardiomyocytes was induced using GSK and Wnt inhibitors. The differentiation protocol was performed automatically using MakCell by replacing the media containing the inhibitors. The positive rate of cardiomyocyte marker cTnT at day 15 of differentiation was evaluated, and a positive rate of approximately 60% was obtained under the conditions of 2 days of GSK inhibitor followed by 2 days of Wnt inhibitor.

Early endoderm differentiation using MakCell

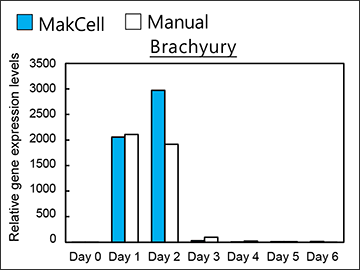

Early mesoderm differentiation of human iPS cells was induced by automatic medium change of three different media using MakCell. By programming the timing of the medium change, we were able to confirm gene expression of Brachyury and PDGFRα by the addition of CHIR99021 as in manual differentiation induction.

Analysis of medium component using MakCell’s culture

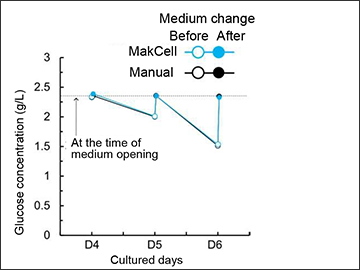

Lactate concentration, glucose concentration, and pH were analyzed before and after automated medium change using MakCell. MakCell was able to remove lactate and provide fresh medium as well as manual operation. There was no difference in the morphology or proliferation rate of iPS cells after 7 days of culture, and the undifferentiated nature of iPS cells was maintained after 2 months of medium change.

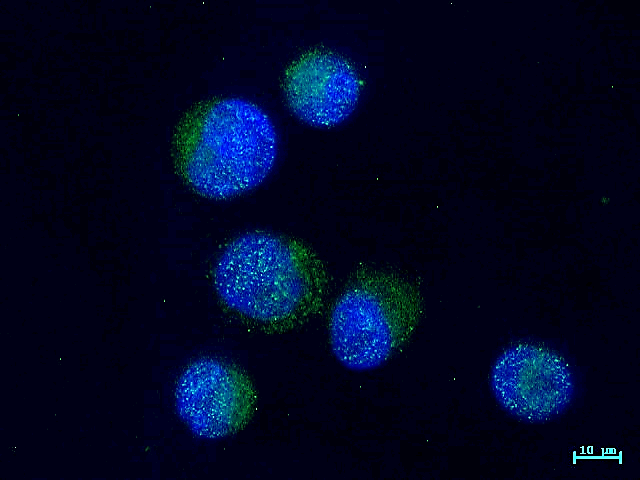

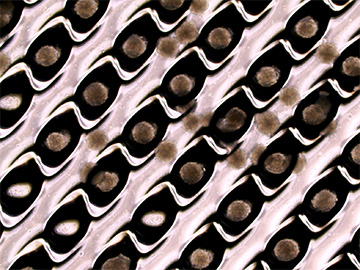

Dimpled plate medium change by MakCell

Using the MakCell for medium change during culture of cell aggregates in a dimple plate, the diameters of the cell aggregates were more uniform than when done manually. MakCell eliminates the need to carry the dimple plate from incubator to bench during medium change. In addition, the drop rate of the culture medium can be set to a constant and slow rate, making it possible to perform tasks that require careful attention during medium change automatically.

Main Specifications

| Model |

MC1000 |

|

|---|---|---|

| Dimensions |

Width 746 mm × Depth 682 mm × Hight 1000 mm |

|

| Weight |

100 kg |

|

|

Power Supply |

AC 100 V 15A | |

| Power Consumption (Device) |

800 W |

|

|

Leakage Circuit Breaker |

Rated Sensitivity Current: 30 mA |

|

|

Display |

6.5 inch LCD touch panel |

|

|

Medium supply line system |

Pump type |

Peristaltic pumps: 3 units |

| Culture Medium Refrigeration |

4~10℃ |

|

|

Medium cooling element |

Peltier element |

|

| Designated bottles |

Corning PET storage bottles 500 mL (model no. 431532) / 1000 mL (model no. 431533) |

|

|

Recommended sterilisation method for nozzles |

Autoclave Sterilizable Stainless Steel Nozzle (MC-NZ) |

|

|

Discard liquid line system |

Pump type |

Peristaltic pumps: 3 units |

|

Designated bottles |

General-purpose wide-mouth bottles (model no. GL-45) |

|

|

Recommended sterilisation method for nozzles |

Autoclave Sterilizable Stainless Steel Nozzle (MC-NZ) |

|

|

Incubator

|

Internal Dimensions |

Width 680 mm × Depth 550 mm × Hight 375 mm |

|

Internal Volume |

140 L |

|

|

Cleanliness of the incubation chamber |

Equivalent to ISO14644-1 Class 5 |

|

|

Maintaining a clean environment in the incubation chamber |

HEPA filter cleaning while circulating air in the incubation chamber |

|

|

Temperature indication |

Digital (Measurement variability of ±0.1 degrees) |

|

|

Temperature Setting |

Touch Panel (0.1℃ Increments) |

|

|

Temperature Setting Range |

20~40℃ |

|

|

Temperature Uniformity |

±0.5℃(at 37℃ setting) |

|

|

CO2 concentration indication |

Digital (Measurement variability of ±0.1%) |

|

|

CO2 Concentration Setting Range |

1.0~20.0% (0.1% Increments) |

|

|

CO2 Gas Supply Pressure |

Approximately 0.1±0.05 MPa |

|

|

Humidification method / Attained humidity |

Natural evaporation from water table / 90%RH or higher |

|

|

Specifications of turntable for culture vessel |

・Simultaneous upper and lower two-tier turntable |

|

|

Settable culture vessels |

・Dishes:60/100 mm |

|

|

Ambient temperature |

20~24℃ |

|

|

Ambient humidity |

30~70% |

|

■MakCell is for research use only.

Consumables

Culture medium tube set

|

Tube set for 500 mL / 1000 mL bottle supply |

||

|---|---|---|

|

Set Contents |

・Electron Beam Sterilized Single-Use Supply Tubes: 15 pcs |

|

|

Model |

MC-DT-500 / MC-DT-1000 |

|

| Recommended replacement frequency |

At the end of each culture |

|

|

Tube set for 500 mL / 1000 mL bottle supply with low adsorption of factors in the medium |

||

|---|---|---|

|

Set Contents |

・Electron Beam Sterilized Single-Use Supply Tubes: 15 pcs |

|

| Model |

MC-DT-CF-500 / MC-DT-CF-1000 |

|

| Recommended replacement frequency |

At the end of each culture |

|

|

Tube set for the discard medium |

||

|---|---|---|

|

Set Contents |

・Electron Beam Sterilized Single-Use Supply Tubes: 15 pcs |

|

|

Model |

MC-ST |

|

| Recommended replacement frequency |

At the end of each culture |

|

Other consumables

|

Air vent filter for culture medium supply bottle cap |

|

|---|---|

|

Sales unit |

15 pcs per unit |

|

Model |

MC-FL |

|

HEPA Filter for the incubation chamber |

||

|---|---|---|

|

Sales unit |

by 1 unit |

|

|

Model |

MC-HF |

|

| Recommended replacement frequency |

Once a year* |

|

|

MakCell Autoclave-Compatible Nozzle |

||

|---|---|---|

|

Sales unit |

by 1 piece / by 6 pieces |

|

|

Model |

MC-NZ / MC-NZ-6 |

|